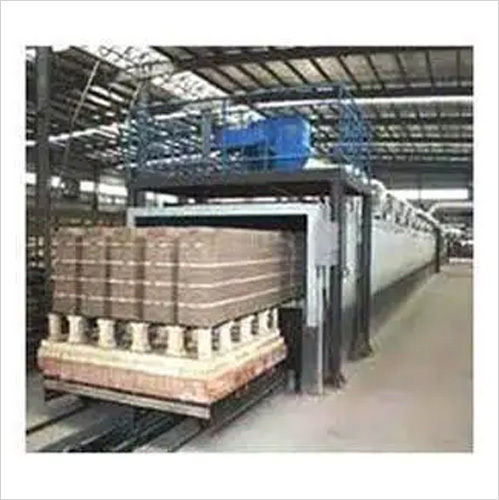

Tunnel Dryer

Tunnel Dryer Specification

- Operating Temperature

- 40-150C

- Heating Method

- Electric Heater/Steam

- Features

- Corrosion Resistant, Easy Maintenance

- Speed Mode

- Variable

- Feeding System

- Conveyor Belt

- Power Source

- Electric

- Function Type

- Drying and Dehydration

- Noise Level

- Less than 75 dB

- Machine Type

- Tunnel Type

- Phase

- Three Phase

- Frequency

- 50/60 Hz

- Automation Grade

- Automatic

- Product Type

- Tunnel Dryer

- General Use

- Industrial Drying of Food, Chemicals, etc.

- Material

- Stainless Steel

- Type

- Continuous Dryer

- Capacity

- 500-2000 kg/h

- Weight (kg)

- 3500 kg

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Free Standing

- Voltage

- 380 V

- Power

- 15 kW

- Dimension (L*W*H)

- 8000 x 1500 x 2200 mm

- Raw Material

- Stainless Steel

- Feature

- Energy Efficient, Uniform Drying

- Color

- Silver/Grey

Tunnel Dryer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Day

- Delivery Time

- 4 Days

About Tunnel Dryer

Tunnel Dryer Manufacturers, are continuous dryers, ideal for drying of Granulated / Extruded / Briquettes / Flakes / Fibrous / Pre Formed materials. The wet materials are loaded in steel or Aluminium trays of the trolleys or in trucks having steel boxes, which move inside the tunnel on rails from the feeding end to the delivery end. The movement of trucks inside tunnel is done with the help of hydraulic pushing arrangement or by automatic chain conveyor pusher drive, having reduction gearboxr timer etc.

This Tunnel Dryer usually consists of a heating tunnel in which feed loaded in trolleys move automatically on rails. The Tunnel Dryer Manufacturers mainly consists of

- Insulated Tunnel

- Rail track

- Automatic motorized doors one at the entry and another at the exit point.

- A hydraulic or chain system for moving the trolleys on to the rail.

- Micron filters to maintain purity, if needed.

- Forced Draft blower to optimally circulate hot air in tunnel for slow & uniform drying.

- Induced draft blowers to suck out moisture laden air from the tunnel.

- Specially designed plates for providing optimal hot air velocity inside the tunnel for effective drying at slow pace.

- Heat Exchangers

- Insulated ducts

- Cooling Zone, if required

- Specially designed Induced draft blower for speedy cooling the hot product, if required, so that it could be packed instantaneously.

- Arrangement for partial recirculation of hot air, if required.

- Automation and control system

- Electrical Panel.

Operation Types :

- Continuous / Semi-continuous/ Batch.

- Single Pass / Multi Pass.

- Single / Multi Temperature & Airflow Controlled Zones.

- Once through / Re-circulating air modules.

Air Flow Patterns :

- Parallel Flow.

- Counter-current Flow.

- Cross Flow.

- Combination Flow.

- Through Circulation.

Material Movement :

- Continuous on Metallic Mesh paddle-dryer-manufacturers.html Conveyor.

- Continuous on chain mounted Moving Trays / Pallets.

- Semi-Continuous on Carts / Trolleys.

- Batch on Trays / Trolleys / Pallets.

Air Heating System :

- Direct Fired / Indirect Fired Air Heaters : Using Liquid / Gaseous Fuels.

- Direct / Indirect Fired Air Heaters : using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc.

- Indirect Air Heaters : Using Steam / Hot Oil / Thermic Fluid.

- Electric Air Heaters: using electricity.

Applications :

- Tunnel dryers are useful for drying large quantity of

- Organic wastes,coconuts, copra,

- fruits,vegetables,

- sliced onions, garlic,

- raw cashew, cashew nuts, ground nuts

- Ceramic Fiber Papers, Ceramic Fiber Boards

- Molded Paper Products

- Rayon Staple, Cotton linters

- Noodles, Food products, etc. Tunnel Dryer Manufacturers.

Specification

| Automatic Grade | Semi-Automatic |

| Design | Customized |

Material Movement:

- Continuous on Metallic Mesh Belt Conveyor.

- Continuous on chain mounted Moving Trays / Pallets.

- Semi-Continuous on Carts / Trolleys.

- Batch on Trays / Trolleys / Pallets.

- Air Heating System :

- Direct Fired / Indirect Fired Air Heaters : Using Liquid / Gaseous Fuels.

- Direct / Indirect Fired Air Heaters : using Solid Fuels, Agro Waste, Saw Dust, Rice Husk, Coal, Briquette etc.

- Indirect Air Heaters : Using Steam / Hot Oil / Thermic Fluid.

- Electric Air Heaters: using electricity.

Highly Customizable for Diverse Applications

The Tunnel Dryer stands out for its flexible design, accommodating multiple layers and customizable tray sizes to suit a wide variety of drying needs. Whether in food, chemical, pharmaceutical, or textile industries, its adaptable features make it ideal for several industrial drying processes. The automatic discharge method and variable speed modes further enhance productivity and throughput.

Energy Efficiency and Uniform Performance

Engineered with energy-saving technology and uniform air distribution supported by axial fans, the Tunnel Dryer ensures even dehydration across all product layers. The grade 304 stainless steel chamber not only resists corrosion but maintains optimal temperature conditions, delivering consistent drying results with minimized energy consumption and noise levels below 75 dB.

Comprehensive Safety and Reliable Operation

Safety remains paramount with integrated features such as overheat protector, emergency stop, and optional humidity control. The PLC-based control system enables precise programming, maintaining stable operation while protecting both the product and operators. The free-standing design and easy maintenance features provide convenience for installation and long-term use.

FAQs of Tunnel Dryer:

Q: How does the forced air circulation in the Tunnel Dryer enhance the drying process?

A: The forced air circulation, facilitated by axial fans, ensures uniform airflow throughout the chamber. This leads to consistent moisture removal, improved heat distribution, and faster drying times, resulting in high-quality end products across all tray layers.Q: What types of industries commonly use the Tunnel Dryer?

A: The Tunnel Dryer is widely applicable in food processing, pharmaceutical, chemical, and textile industries. Its robust design and versatile configuration support the drying and dehydration of various raw materials, making it an essential tool in industrial environments.Q: When is it advisable to opt for the optional humidity control feature?

A: Humidity control is recommended when processing sensitive materials that require precise moisture levels. This feature helps maintain optimal drying conditions, improving product quality and reducing the risk of over-drying or uneven dehydration.Q: Where can the Tunnel Dryer be installed, and what is its installation type?

A: The Tunnel Dryer features a free-standing installation design, making it suitable for placement in factories, processing plants, and production facilities requiring industrial drying solutions. Its robust construction and sizable dimensions support seamless integration into existing workflows.Q: What safety features are included in the Tunnel Dryer to protect operators and materials?

A: Key safety mechanisms include an overheat protector, emergency stop button, and optional humidity control. These features minimize the risk of accidents or product damage, ensuring safe, reliable operation for extended periods.Q: How is the drying time and temperature adjusted for different products?

A: Drying time, set between 30 and 180 minutes, and temperatures ranging from 40C to 150C, are precisely controlled via the PLC control system. Operators can adjust these parameters to suit specific product requirements and achieve optimal drying results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dryers-Systems Wise Category

Spin Flash Dryer

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Feature : Other, Uniform Drying, High Efficiency

General Use : Drying of Heat Sensitive Material

Features : Energy Efficient, Continuous Operation

Control System : Other, PLC Based

Continuous Fluid Bed Dryer

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Feature : Other, Low Maintenance, High Efficiency

General Use : Industrial Drying and Granulation

Features : Uniform Drying, Low Energy Consumption

Control System : Other, PLC Based

Continuous Conductive Vacuum Dryer

Minimum Order Quantity : 1 Piece

Voltage : 380V

Feature : Other, High Drying Efficiency

General Use : Industrial Drying of Heat Sensitive Materials

Features : Continuous Operation, Uniform Drying, Energy Efficient

Control System : PLC Control

Agitated Thin Film Dryer

Minimum Order Quantity : 1 Unit

Voltage : Customizable

Feature : Other, Agitated Thin Film

General Use : Chemical pharmaceutical industries

Features : Efficient drying robust design

Control System : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry