Call: 07313726518

Brick Manufacturing Plant Turnkey Project

MOQ : 1 Unit

Brick Manufacturing Plant Turnkey Project Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 4 Days

About Brick Manufacturing Plant Turnkey Project

Voice Engineers offer modern, state of art brick manufacturing plant. The system is designed to carry out all the processes in brick making mechanically in a continuous manner so as to minimize application of labour, standardize the products and produce high quality bricks. These result into customer satisfaction, high profitability and repeat orders.

The brick manufacturing system designed by Voice Engineers broadly involve the following steps :

Grinding and sizing of raw materials

- Each ingredient of brick making is separately subjected to screening and to crushing of its large particles in jaw crushers. This is followed by grading and recrushing of over size particles in hammer mill. Finally the correct sizes of all ingrdients in the required proportion are mixed together.

Blending & extrusion

- Pulverized ingredients and water are fed into one end of a pug mill, which uses knives on a rotating shaft to cut through and fold together materials in a shallow chamber. The blend is then fed into an extruder at the far end of the mill. The extruder usually consists of two chambers. The first removes air from the ground clay with a vacuum, thereby preventing cracking and other defects. The second chamber, a high-pressure cylinder, compacts the material so the auger can extrude it through the die. After it is compressed, the plastic material is forced out of the chamber though a specially shaped die orifice. The cross-section of the extruded column, called the "pug," is formed into the shape of the die. Sections of desired length are cut to size with rotating knives or stiff wires.

- Chamfering is done to produce a furrow in brick for paving applications. Here rollers are used to indent the brick as it is being extruded. Sometimes wire cutters are deployed to do the chamfering and cutting in one step.

Drying

- This is for removal of excess moisture before firing the brick. Otherwise, water will burn off too quickly during firing, causing cracking.

- Voice Engineers offer Tunnel dryer which use cars to move the brick through humidity-controlled zones that prevent cracking. This consists of a long chamber through which the bricks loaded in a trolley are slowly pushed. Forced Draft fan-circulates hot air into thje chamber, speeding up the drying process.

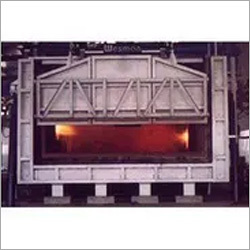

Firing

- Dried bricks loaded on cars on coming out of the tunnel dryer are introduced seamlessly on a continuous basis into high temperatures furnaces called kilns. Kilns are fired using solid fuels such as sawdust and coal.

- On completion of firing process, the bricks are cooled and stacked. Stacking can be done both manually and mechanically. In modern brick manufacturing plants, automated setting machines are preferred to cut on the costly labout.

Comprehensive Turnkey Solutions

We deliver end-to-end project management for brick manufacturing plants, from design and installation to commissioning and operational training. Our expertise in plant layout customization means every client receives a solution that maximizes efficiency and meets specific production targets, regardless of facility size.

Advanced Control Systems for Seamless Operation

Our plants integrate PLC-controlled systems, allowing for precise process management and consistent brick quality. This automation reduces the need for skilled labor, minimizes operational errors, and ensures quick cycle times, making the entire production more productive and cost-effective.

Versatile Output with Wide Fuel Compatibility

Adaptable to electric, coal, or diesel fuel sources, our manufacturing plants guarantee high output per shift for both standard and bespoke brick sizes. Whether meeting routine demands or unique project needs, the system supports continuous operation, maximizing throughput and profitability.

FAQs of Brick Manufacturing Plant Turnkey Project:

Q: How does the PLC control system benefit brick manufacturing operations?

A: The PLC control system automates and streamlines the entire production process, ensuring uniform brick quality and reducing the possibility of operational errors. This automation contributes to faster cycle times, higher efficiency, and lower manpower requirements, making operations both reliable and cost-effective.Q: What types of bricks can be produced with this plant?

A: Our plant supports the production of both standard-sized and custom-sized bricks, allowing customers to fulfill typical market demands as well as specialized project requirements with flexibility and efficiency.Q: When can installation and commissioning support be expected?

A: Installation and onsite commissioning support are provided as part of the turnkey project, scheduled according to the clients timeline to ensure prompt setup and minimal disruption to operations.Q: Where does customization come into play within the plant layout design?

A: Customization is integral, with plant layouts tailored to each clients available space, operational flow, and production goals. Our design experts work closely with clients to ensure optimal efficiency, safety, and expansion capabilities.Q: What is the typical output efficiency per shift for this brick plant?

A: The plant is engineered for high output efficiency per shift due to its continuous operation, fast cycle times, and automated systemsresulting in impressive productivity and rapid return on investment.Q: How many workers are required to operate the plant, and what skills do they need?

A: Only a low number of semi-skilled workers are required for daily operation due to the plants advanced automation and control systems. Our team provides comprehensive operational training as part of the installation process.Q: What after-sales services are available for this brick manufacturing plant?

A: We offer comprehensive after-sales support that includes maintenance guidance, spare parts supply, technical troubleshooting, and periodic performance evaluations to ensure smooth and consistent plant operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry