Call: 07313726518

Tyre Oil Turnkey Project

MOQ : 1 Unit

Tyre Oil Turnkey Project Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 4 Days

About Tyre Oil Turnkey Project

HIGH LIGHTS

- Highly profitable project - very low pay back period

- Easily available raw material ( waste tyre ) and automatic sales of products

- Environment friendly - pollution free design

- Low investment - SSI unit

- Easy to operate - automatic operation

USES OF THE PRODUCTS

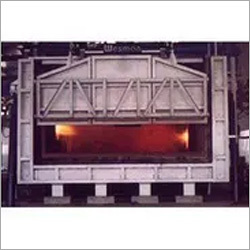

- Tyre / Fuel oil : As fuel in boilers, furnaces. In fact it is widely used as industrial fuel to substitute furnace oil or industrial diesel.

- Wire : In steel melting shops as scrap for making steel

- Carbon : As solid fuel in boilers or in furnaces & ovens.

TECHNOLOGY & PROCESS

On heating waste tyre in an oxygen free environment at a temperature of 300 - 350 deg C, it does not burn, but gets subjected to a thermo-chemical reaction which yields gases as its main product. Condensable part of the gas upon condensation becomes fuel oil and non condensable part is diverted to the furnace of the plant for heating up the tyre. Steel wire and carbon are separated as the secondary products of the plant.

- Our cooling tower is designed to ensure effective condensation of gases, thereby increasing the output of oil by 2%.

- Non condensable part of the generated gases are used to sustain the heating process

without the need of any alternate fuel.

- The surplus non condensable gases are burnt in a hub and then passed through a water scrubber before getting released in the air through a long chimney.

- Special rotating ring plating with steel rollers reduces risks of erosion of the sheet.

- Screw conveyor system transfers the carbon to the storage without pollution.

- Reactor function is designed for a noiseless rotation.

- Adequate safety precautions are in built in the system

High-Efficiency Waste Tyre Conversion

This turnkey plant transforms waste tyres into commercially valuable products like tyre oil, carbon black, steel wire, and byproduct gas. With optimized automation and energy use, the process operates at power ranges from 45160 kW, adapting to plant size and output requirements. The robust steel construction provides long-lasting durability while highly controlled processes elevate efficiency and safety.

Advanced Automation and Safety Controls

Equipped with a PLC/SCADA system, the plant ensures precise operational management and real-time safety monitoring. Its interlock features provide dependable protection against operational hazards, while detailed safety mechanisms help maintain seamless and worry-free production for continuous or batch operation.

Comprehensive Service and Flexible Installation

Our turnkey installation covers the entire projectfrom delivery and commissioning to on-site staff training. With flexible plant sizing (300010000 sq.ft.) and diverse heating options, the system adapts to various industrial setups. The after-sales support ensures sustained plant performance and peace of mind for operators.

FAQs of Tyre Oil Turnkey Project:

Q: How does the Tyre Oil Turnkey Project work?

A: The plant processes waste tyres using pyrolysis, breaking them down in a controlled, oxygen-free environment. Under high heat provided by fuel oil, gas, or wood, tyres are converted into tyre oil, carbon black, steel wire, and gas, using water condensation for cooling and advanced automation for efficiency.Q: What are the primary benefits of installing this turnkey project?

A: Major benefits include converting waste tyres into high-value products, reducing environmental impact, and generating additional revenue streams. The fully automatic, PLC/SCADA-controlled operation enhances safety, efficiency, and operational ease, while turnkey installation and training ensure fast project ramp-up.Q: When should a business consider using a tyre oil plant?

A: Businesses generating significant amounts of waste tyres, or looking to diversify into resource recovery and recycled materials, should consider this solution. Its ideal for locations with space availability of 300010000 sq.ft. and industries aiming for sustainable waste management.Q: Where can the Tyre Oil Turnkey Project be installed?

A: The project is suitable for both industrial facilities and recycling hubs with the specified area and utility connections. Designed for the Indian market, it accommodates voltage ranges between 240380V and space requirements based on desired capacity.Q: What is included in the after-sales service?

A: After-sales support covers on-site installation, commissioning, and comprehensive staff training. Our team ensures the plant operates optimally from the start and provides continued assistance to maintain productivity and safety standards.Q: How is the output from the plant utilized or sold?

A: Tyre oil can be used as alternative fuel for industrial boilers or generators, carbon black is applicable in rubber and pigment industries, and recovered steel wire may be recycled for steel manufacturing. Generated gas can supplement the process heating or be sold commercially.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry