Black Salt Manufacturing Plant Turnkey Project

Black Salt Manufacturing Plant Turnkey Project Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 4 Days

About Black Salt Manufacturing Plant Turnkey Project

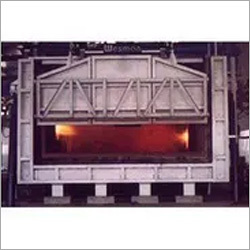

Black Salt Manufacturing Plant

Black salt, is a pungent-smelling salt. This condiment consists mainly of sodium chloride with several other ingredients, like, sodium sulphate, sodium bisulfate, sodium sulphide, Iron sulfide and hydrogen sulfide. These trace compounds lend to the black salt its colour and savory smell. The smell is largely due to its sulfur content.

Black salt is made by melting a mixture of common salt, charcoal along with small quantities of harad seeds, aamla, bahera, babul bark, etc., Salt melts at 801 0C, though other ingredients melt at a much lower temp. On melting, salt and other ingredients make a homogeneous coloured solution. Allowed to cool, the solution transforms into a hard coloured crystal. This is called black or coloured salt.

Present method of making black salt dates back to ancient times and is extremely cumbersome. Common salt after getting mixed with additives, is poured into an earthen pot. A number of such pots are placed in a make shift coal fired furnace. It takes nearly 5 - 7 hours in completion of melting. On melting, the insoluble impurities settle down at the bottom of the pot. Subsequently, the fire is extinguished and molten mass is left for cooling for very long hours. On cooling the earthen pots filled with solid salt, are broken and the solid mass is taken out. Insoluble impurities accumulated at the bottom of the solidified mass are separated from the main body of rock salt with the help of hammer and chisel. The main body of rock salt too is broken into small pieces with the help of hammer. The whole operation is labour intensive, cumbersome, arduous and time taking.

Voice Engineers, in keeping with its tradition of innovating process technologies, has developed a path breaking process for manufacturing black salt. The development has taken several months and more than a dozen trials. It was a big challenge. But we finally succeeded in developing a modern state of art mechanized black salt plant.

The process involves mixing of salt with other ingredients, their melting, solidifying and pouring of the black salt from the pot.

Advantages over the traditional process:

- Our black salt plant ensures

- Just a couple of operators and workers.

- Drastic reduction in production time.

- Lower energy consumption

- Convenience.

- Better and uniform quality

- Higher production

- Acceptable level of emission

- Lower cost of production

Specification

| Automatic Grade | Semi-Automatic |

| Design | Customized |

Advanced Technology for Superior Black Salt

Our turnkey solution utilizes state-of-the-art purification and processing technology, ensuring consistent quality and optimal efficiency in black salt manufacturing. Automated controls and intelligent design streamline operations, reducing power consumption while maximizing yield. With a focus on safety and performance, the plant is crafted from stainless steel, making it robust, corrosion-resistant, and built for longevity in demanding industrial environments.

Tailored to Your Requirements

This black salt manufacturing plant offers flexibility, with fully customizable layouts and production capacities. Whether your focus is on small-scale specialty batches or large-scale continuous production, our expert team will configure the plant to fit your facilitys size and output needs. With automation, low maintenance, and minimal noise, the design prioritizes operator comfort and operational reliability.

Comprehensive Support and Compliance

From installation handled directly on-site to comprehensive training and after-sales support, our service covers every aspect of plant integration. The system operates under strict environmental regulations, meeting international standards to ensure a responsible, sustainable production process. With PLC-based controls and easy-access components, ongoing maintenance is straightforward, keeping downtime to a minimum.

FAQs of Black Salt Manufacturing Plant Turnkey Project:

Q: How does the black salt manufacturing plant ensure high output with low power consumption?

A: The plant employs the latest automated salt purification and processing technology, which streamlines operations to maximize productivity while minimizing electricity usage. Its efficient motors and smart control systems help reduce waste and optimize performance.Q: What customization options are available for the plant layout and capacity?

A: We offer full customization of both the plant layout and production capacity to align with your specific space and output requirements. Whether you need compact facilities or large-scale production, the plant can be tailored for seamless integration.Q: When and where is the plant installed, and who manages the installation?

A: Installation is performed directly on-site at your preferred location in India, with our expert team handling the entire setup. We ensure the plant is operational and integrated with your infrastructure before project handover.Q: What is the operating temperature range, and how does it affect the production process?

A: The plant operates efficiently at temperatures up to 350C, supporting effective purification and processing of black salt. This temperature range ensures optimal quality and consistency in the final product.Q: How does the plant support easy maintenance and low downtime?

A: Designed for straightforward upkeep, the plant features easy-access components and rugged stainless steel construction. Its modern, PLC-controlled system provides reliable operation, contributing to minimal maintenance and reduced downtime.Q: What are the main environmental and noise compliance features of the plant?

A: The plant complies with international environmental standards and operates at noise levels below 65 dB. This ensures minimal disturbance and aligns with rigorous environmental and workplace safety regulations.Q: What are the benefits of choosing this turnkey project for black salt manufacturing?

A: By opting for our turnkey solution, you benefit from high operational efficiency, comprehensive training and support, a flexible, future-ready plant design, and full compliance with industry standardsensuring a smart and sustainable investment for your production needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry